If you’re exploring the realm of fabric customization it is crucial to understand the textures and effects offered by each type of heat transfer vinyl. You may have come across flocked vinyl and puff vinyl in your projects. Do you know how they differ? While both have the power to transform fabrics into captivating artworks they possess qualities that set them apart.

When you embrace flocked heat transfer vinyl you add a layer of texture to your projects that resembles the softness of velvet. On the hand 3d puff HTV is renowned for its three dimensional effect that truly stands out giving your designs a vibrant appearance when heated. These vinyl types not only bring color and patterns, but also introduce an extraordinary texture to elevate the overall aesthetic of your product.

Now let’s delve deeper into their composition, application techniques and ideal use cases. By understanding their attributes you’ll be able to choose the right vinyl for your upcoming project and achieve captivating results. The subtle nuances in selecting the vinyl can take your work from good, to exceptional.

“The only limit to our realization of tomorrow will be our doubts of today.”

– Franklin D. Roosevelt

Table of Contents

Is Flocked Vinyl the Same as Puff Vinyl?

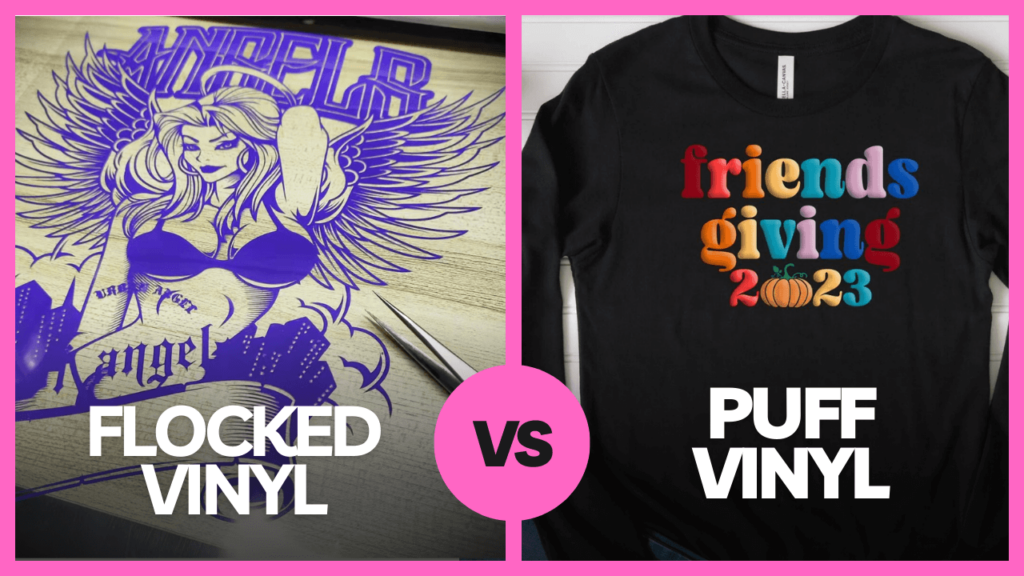

When comparing Flocked Vinyl and Puff Vinyl there are distinctions to keep in mind. Flocked iron-on vinyl inherits an embossed effect when it was produced, while puff vinyl is flat when it was first manufactured, then it puffs up only when certain temperature and time applies on it. Usually puff vinyl is more visually appealing and eye catching than flock vinyl cause its thickness or depth is higher.

Design a captivating image that visually compares flocked vinyl and puff vinyl. Use colors and textures to highlight the distinctions between these two materials. Showcase both types of vinyl on a shirt to emphasize their application in heat transfer. Utilize shapes and patterns to represent the qualities of each material ensuring a balanced composition in the image.

When it comes to diving into the world of vinyl projects having an understanding of heat transfer vinyl (HTV) is essential. HTV acts as a layer that allows creative individuals like yourself to apply designs onto various fabrics. The key to achieving flawless results lies in the combination of heat and pressure – the magic that brings your vision to life. Just imagine the excitement of turning garments into a pieces of art by using flocked HTV or adding a touch of elegance to home decor with iron on vinyl.

To get started make sure your Cricut or Silhouette machine is ready for action as they will be your companions when cutting vinyl. Working on a project involving cut flocked HTV vinyl requires precision – you’ll need to navigate through the cutters settings with the finesse of a conductor leading an orchestra. As your machine etches out your design the delicate dance between the blade and vinyl takes place resulting in a cut thats ready for next step.

If your cut setting is proper, then both are easy to weed. As you move on to applying flocked HTV it becomes a performance where your home iron or heat press takes stage while fabric serves as the backdrop for your creation. With each press you apply heat and exert pressure on it, like taking a pause within the excitement of crafting itself.

Then when you reach the climax carefully remove the backing sheet to reveal your vinyl masterpiece, with warm or cold air giving it life.

Remember: having a grasp of the basics of HTV will help you tackle intricate vinyl projects such as flocked designs and playful puffy textures. The table below provides guidance for beginners:

| Material Type | Cutter Settings | Application Technique | Removal Method |

| Flocked HTV | Deep Blade Increased Pressure | Medium Heat, Firm Pressure | Warm/Cold |

| 3d Puff Vinyl | Deep Blade Increased Pressure | Medium Heat, Firm Pressure | Warm/Cold |

| Regular HTV | Standard Blade, Regular Pressure | Medium Heat, Pressure | Hot/Warm/Cold |

| Glitter/Metallic HTV | Deep Blade High Pressure | High Heat, Firm Pressure | Cold |

| Printable HTV | Standard Blade | Regular Pressure Medium Heat, Pressure | Warm/Cold |

Exploring the world of fabrics and textiles further your newfound understanding of heat transfer vinyl will be both a guiding force and a source of inspiration. Whether you’re applying flocked iron on vinyl to a sweatshirt or bringing details to life on a canvas tote bag the principles of HTV will lead you to unleash your creative potential. May the fabrics, under your wings remain vibrant as you cut and weed off and make your way into the crafting hall of fame.

What Makes Flocked Heat Transfer Vinyl Different

When it comes to enhancing your crafting projects flocked heat transfer vinyl is a game changer, with its textured appeal. The feel of the fabric after application offers a depth and sensory, or even, luxious experience that sets it apart from other types of vinyl. If you’re considering using flocked iron on vinyl for your project understanding its qualities will help you make the most of its potential.

The Soft and Plush Appeal

The allure of flock HTV lies in its plush appearance, which adds a touch to any piece. This velvety texture, reminiscent of suede creates a raised visual feast. Tactile effect that distinguishes your designs from standard vinyl finishes.

Whether you’re creating custom apparel or aiming to infuse an element into your home decor the velvet like finish of flocked HTV has the power to transform the ordinary into something amazing. The texture of the fabric takes on prominence and sophistication when adorned with this material.

Cutting Settings and Application

To utilize flocked heat transfer vinyl it’s important to adjust your approach to both cutting and application techniques. Due to its thickness tuning the cut settings within your design space becomes essential for results. To achieve a cut through the flock material you can try adjusting the blade setting deeper and reducing the cutting speed if necessary.

When it’s time to transfer your design onto the fabric using a heat press correctly is crucial. Applying a level of heat and pressure will ensure that the fibers adhere well resulting in a durable and visually appealing outcome. It’s important to follow practices when working with flocked heat transfer vinyl to achieve a high quality look.

Flocked HTV is compatible with Cricut machines. Can be used for DIY projects. You can unleash your creativity by making custom t shirts, decorative throw pillows, unique tote bags, personalized hats or stylish wall art right from the comfort of your home. Flock HTV is designed to handle these tasks with ease.

People often discuss two types of vinyl for crafting; flocked vinyl and puff vinyl. When you dive into personalizing fabrics and textiles understanding the differences, between these two options can greatly impact your projects.

When heat is applied something magical happens to puff HTV. Initially flat and when heat applied, it takes on a new dimension. This expansion creates captivating designs that seem to jump off the fabric. On the other hand flocked HTV maintains its velvety appearance after heat application as its texture is specifically designed to remain consistent.

But be remindful that puff vinyl are more likely to get wrinkles or bubbles of your heat settings is imcorrect. In this case, please alwasy refer to the users manual of its manufactuers, or you can simply learn the basic of how to apply puff vinyl in this article.

Creating Attention Grabbing Designs

Both flocked and puff vinyl have appearances that serve different design purposes.

If you’re aiming for an refined touch, in your projects consider using flock vinyl. It has a suede feel that adds an sophisticated look to your designs. The raised fibers of flocked vinyl create an effect enhancing the tactile experience. On the hand if you want to create something playful and visually unique puff heat transfer vinyl is the way to go. It adds a texture that makes your creations stand out and make a statement. Unlike other type of heat transfer vinyl, both offers an extraordinary finish ensuring that your work doesn’t fade into the background.

In summary choosing between flocked vinyl and puff vinyl depends on the appearance you desire and the sensory experience you want to provide with your designs. Both options deviate from heat transfer vinyl. Cater to different preferences within custom fabric design.

Key Differences Between Flocked and Puff Vinyl

When exploring the world of heat transfer vinyl it’s important to understand what sets flocked and puff vinyl apart. Not will this knowledge contribute to the success of your project. It will also ensure that the results have the desired tactile and visual impact.

Physical Distinctions and Attractiveness

The dissimilarity, between flocked and puff vinyl lies in their characteristics. Fuzzy flocked vinyl adds an textured finish, to your textile projects. Unlike HTV this type of vinyl is thicker. It has a plush feel that you can actually feel when you touch it. Its suede like surface instantly grabs attention. Turns any fabric into a piece of art. While puff vinyl comes to life under heat press expanding and creating a 3D effect in your designs without having a prominent texture before application.

When it comes to choosing the vinyl for your project it’s like an art form itself. If you’re working with fabrics and want a look flocked vinyl is the way to go. It delivers tactile experiences. Is perfect for statement pieces or garments that need extra warmth and luxury. On the hand puff vinyl has a feel to it and works well with thin fabrics. It adds drama to your visuals without overwhelming the material making it great, for eye catching designs without adding weight.

Features

Flocked Vinyl: It has an velvety texture, before application and after applying it creates a raised surface. This type of vinyl is thicker than HTV. Works well on heavier fabrics for bold looks.

Puff Vinyl: It has an smooth texture before application. Once applied it gives an inflated 3D effect. The thickness of puff vinyl is comparable to HTV. It works best on fabrics to create contrast.

When deciding between flocked vinyl and puff vinyl for your project consider the desired effect you want to achieve and the nature of your project. Understanding these differences will help you make creative decisions.

Insider Tips for Excelling in Vinyl Projects

Embarking on the journey of vinyl crafting opens up a world of creativity. To navigate this realm with finesse like a crafter it takes more than passion; you need the right tools and knowledge to use them effectively. Here’s how you can set yourself up for dazzling results that exude professionalism.

Essential Tools:

There are tools, for vinyl crafting but some essentials remain constant. A precision cutter becomes your companion ensuring that your designs come to life with edges and intricate lines.

Remember, when you’re cutting vinyl it’s important to adjust the settings on your cutter. Flocked HTV is thicker, than normal HTV. It requires a deeper cut to ensure a successful transfer.

Pay attention to the details and techniques. Make sure the shiny side of your flocked vinyl faces downwards when you place it on the cutter. Then flip it over before using the heat press.

When its time to use the heat press set it at 320°F. Apply pressure for 15 seconds. As you wait for the timer to count down anticipation builds up. Once you lift the press your design will shine under the spotlight. Let it cool down for adhesion to fully set in and give your project a long lasting finish.

Immerse yourself in the world of vinyl crafting with confidence knowing that these tips will bring your projects to life with a fun and professional quality that’s rewarding both during and after creation.

Conclusion

Now that you have all the information about flocked and puff vinyl you find yourself at the point of choosing the material to breathe life into your vinyl projects. Flocked vinyl offers a texture to suede or felt providing a luxurious depth and tactile sensation that is perfect for giving any creation a soft and exquisite touch. Its plush surface ensures that every design exudes sophistication, highlighting edges and fine details with elegance.

However, puff vinyl adds a twist to regular flat vinyl. When exposed to heat this material springs into a puffy effect that adheres temporarily to the carrier sheet before proudly standing out from the base fabric. Its inflated appearance is sure to catch the attention by adding an appeal.

Whether you’re inclined towards the cushioned feel of flocked heat transfer vinyl or aiming to make a statement with the nature of puff HTV, your choice should align with your desired look while accommodating the specific texture of the fabric you’re using. As you embark on your project be confident, in knowing that your comprehensive understanding of these materials will result in a masterpiece that perfectly reflects your envisioned aesthetic.

FAQs:

What are the main differences between flocked vinyl and 3d puff heat transfer vinyl?

Flocked vinyl features a fuzzy, velvety texture that’s pre-embossed, creating a suede-like effect on your finished projects, and it’s thicker than regular heat transfer vinyl. Puff vinyl, however, starts flat and only expands to a 3-D puffed appearance when heat is applied. This effect can add more visual intrigue to your design.

What sets flocked heat transfer vinyl apart from other HTV materials?

Flocked HTV is recognized for its unique fuzzy and furry appeal, providing a textured finish to the fabric that differs from the typical flat and smooth look of regular HTV. It also requires specific cut settings and a little more heat and pressure during application due to its thicker composition.

Can flocked and puff heat transfer vinyl be used with a Cricut machine?

Yes, both flocked and puff heat transfer vinyl are compatible with Cricut machines as well as other similar cutting devices. They simply require different cut settings and application processes to achieve the best results.

How does puff vinyl transform when heat is applied?

Puff vinyl undergoes a significant transformation when heat is applied during the transfer process. It begins as a flat design and then expands or ‘puffs up’ to create a three-dimensional, eye-catching effect on the fabric.

What types of projects are best for flocked vinyl?

Flocked vinyl is excellent for projects where a bold, tactile design is desired, such as on heavier fabrics or items where the texture can be a focal point. Examples include custom T-shirts, tote bags, and home décor where a soft, velvety touch adds elegance or a playful vibe.

Are there specific techniques for achieving a professional look with vinyl projects?

Yes, to achieve a professional look, it’s important to cut the vinyl with the shiny side down, use the correct heat and time settings (typically around 320°F for 15 seconds), and allow for a cooling period before peeling the carrier sheet. A consistent practice of making a test cut before your final cut can also help in nailing down the perfect settings for your materials.

How do I know which cut settings to use for flocked or puff heat transfer vinyl?

Since flocked HTV is thicker than regular HTV, it requires deeper cut settings. For puff HTV, standard cut settings generally work, but you should always check the manufacturer’s recommendations and perform a test cut to find the optimal settings for your specific cutter machine and vinyl type.